OSHA Training

English and Spanish Classes available

Companies who have employees in need of training can contact us to request a proposal for an on-site class or training can be performed at our training center. We employ professional trainers with extensive experience, and we certify using OSHA requirements. Students who complete the OSHA 10 or 30 hour class receive the official OSHA Outreach Training wallet card. We are professionals leading the way in training, compliance, and consulting. With years of regulatory research, education and direct worksite experience, we developed some of the most comprehensive and easy-to-learn training materials. We also offer flexible training that can be tailored to your specific requirements.

- CPR-Adult

- Rescue breathing

- Choking victims

- Soft tissue injuries

- Controlling the bleeding

- Fractures/immobilization

- Heat and cold injuries/shock

- Hands-on training for simulated accidents and injuries

Necessary for anyone who has the potential of exposure to diseases carried by blood and other bodily fluids & materials. The student will gain an understanding of how to protect themselves from Bloodborne pathogens. The course is based on the OSHA standard on Bloodborne pathogens along with other resources to ensure accurate and current information is presented. The course is essential for employees designated as first responders.

- Regulatory requirements

- Potentially infectious materials

- Routes of entry and exposure

- Exposure control and P.P.E.

- Universal precautions

- Engineering controls

- Roles and responsibilities

- Hazards of confined spaces

- Job site entry plan

- Atmospheric testing

- Ventilation

- Permit process

- Principles of electricity

- Hazards of electricity

- Electrical standards

- Safe work practices

- Approach distances

- Electrical-related injuries

- Electrical hot work

- Regulatory requirements

- Principles of fall protection and hazards

- Fall arrest systems and components

- Inspection and proper fit of PFAS

- Competent person

- Classes of fires

- Elements of the fire triangle

- Types of fire extinguisher and agents

- The PASS method and it's importance

- Explanation of job site fire safety

- Clothing

- Flagger equipment

- Proper flagger position

- Advance warning signs

- Traffic operations

- Basic rules of safety

- Regulatory requirements

- Principles of the forklift truck

- Proper operation techniques

- Inspection and maintenance

- Fueling/Charging procedures

- Hands-on practice (if necessary)

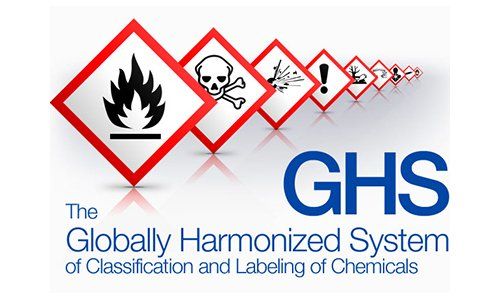

The New Hazard Communication requires the Globally Harmonized System of Classification and Labeling of Chemicals. The Globally Harmonized System (GHS) was created by the United Nations and serves as the international standard for Hazard Communication. Recent changes to the OSHA Hazard Communication Standards have aligned with the GHS, and training is required to familiarize companies on these changes. With our tranining, you will learn important information about changes to hazard classification standard, labels, safety data sheets, as well as employee training requirements.

- (Intro) Hazard Communication

- Hazard Classification

- Written Hazard Communication Program

- Labels & Other Forms of Warning

- Safety Data Sheets (SDS)

- Employee Information & Training

One of the most commonly used tools to determine how to safely perform a task or job is the Job Safety Analysis (JSA). This tool allows an individual to easily review job methods to uncover hazards. A JSA can benefit a company in many ways such as individual training, preparation for irregular jobs, review of procedures after accidents or job improvements. ESC will lead the student through the correct use and development of a Job Safety Analysis.

- Benefits of a JSA

- Discovering hazards

- Development of the JSA

- Application of the JSA to a task

- Sample JSA review

Control of hazardous energy commonly referred to as lockout/tagout is a strictly enforced OSHA Standard 29 CFR 1926.417. One of the key aspects of the regulation is the training of all authorized employees (those using the procedure to perform lockout/tagout work). Authorized employees must be trained to properly use energy control procedures to safely perform maintenance, servicing, or installation work where hazardous energy could cause an injury. The class includes a demonstration of typical lockout/tagout devices.

- Control of hazardous energy

- Authorized/affected employees

- Energy control devices

- Energy control procedures

- Lockout/Tagout steps

Hardhats, safety glasses, and protective gloves are just some forms of personal protective equipment that are used daily by employees in different industries. Understanding when & what PPE is necessary, how to properly wear/adjust, the limitations of PPE, and the proper care, maintenance, useful life, and disposal of PPE are requirements under OSHA Standards 29 CFR 1910.132.

- Need for PPE

- Head protection

- Eye and face protection

- Hearing protection awareness

- Respiratory protection awareness

- Hand and Foot protection

- Protective clothing

- Hazard assessment

- Basic hitches

- Using volume to calculate load

- Trial method to find center of gravity

- Sling tension & load angle factor

- Rigging configurations

- Working load limits

- Vertical, side & improper loading

Topics Presented

- The nature of scaffold hazards

- Design criteria, capacities, and use

- Operation and inspection of scaffolds

- Electrical, fall, and falling

- Object hazards

- Fall protection during scaffold erection

- What is Crystalline Silica

- Exposure control plan

- Exposure assessment

- Methods of compliance

- Regulated areas

- Respiratory protection

- Housekeeping

- Medical surveillance

- Training

This course will briefly explain the purpose of the Steel Erection Negotiating Rulemaking Advisory Committee (SENRAC). Highlights of the Steel Erection Standard include its Scope & Application, definitions and the role of the controlling & sub-contractors. This course covers site layout, site-specific and construction sequence, hoisting & rigging and structural steel assembly.

Topics Presented

- Multiple lift rigging

- Working under loads

- Walking/Working surface hazards

- Plumbing-up

- Hoisting, landing & placing decking

- Repair, replacement or modification

- Erection of joists & girders

- Fall Protection

- The hazards of trenching & excavation

- Proper sloping, benching, & shoring

- Trench shield methods

- Highlight of the the OSHA standard

- Soil classification

- Proper use of P.P.E.

- Current traffic standards

- Accident potential & legal liabilities

- Simple traffic control plans

- Typical construction activities

- Basic flagging techniques

- Traffic Control Devices

ESC Safety Consultants is proud to be associated with

Providing A Safe Workplace For Construction & General Industries Since 1981

Providing A Safe Workplace For Construction & General Industries Since 1981

Contact Information

1307 North Glenville Drive

Richardson, Texas 75081

Phone: (214) 575-8710

Toll Free: (800) 327-1516

Company Links